Are you involved in designing or sourcing USB chargers? Do you wonder how manufacturers juggle conflicting requirements? You need to understand the balance between efficiency, density, and safety.

Designing a great USB charger isn’t just about making it charge fast. It’s a complex act of balancing different goals. You want it small, powerful, efficient, and absolutely safe. Achieving all four at once is a challenge. As someone who’s seen countless charger designs evolve, I know the trade-offs involved.

Early chargers were bulky and not very efficient. Then came smaller ones, but sometimes safety was an issue. Now, with GaN technology, we can get high power in small sizes, but it still requires careful engineering to stay safe and efficient. It’s a constant push and pull between these factors.

Why is Balancing These Factors Crucial for Charger Design?

Are you thinking you can just maximize one factor, like power density? Are you wondering why you can’t just make the smallest, most powerful charger possible?

Balancing these factors is crucial because neglecting any one can lead to major problems. An inefficient charger wastes energy and generates heat. A high-power-density charger that isn’t designed well can overheat and become a safety hazard. An unsafe charger is unacceptable.

I’ve seen designs that prioritized size so much that they sacrificed thermal management, leading to reliability issues. I’ve also seen very safe, reliable designs that were just too big or too inefficient to be competitive. A successful charger finds the sweet spot. It’s about optimizing the design for the intended application and market.

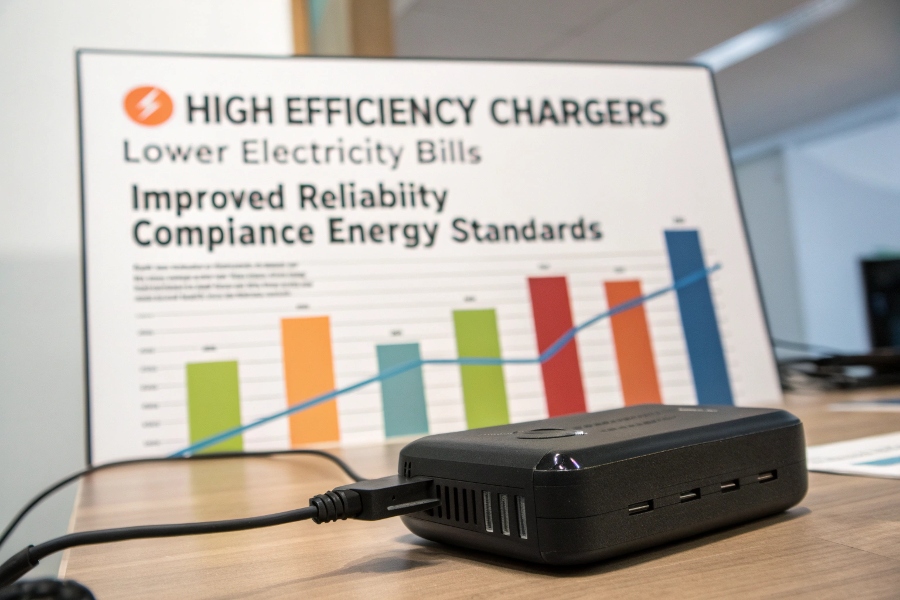

Energy Efficiency1

Higher energy efficiency means less power is wasted as heat during charging.

| Benefit of High Efficiency | Impact |

|---|---|

| Less wasted energy | Lower electricity bills for consumers |

| Less heat generated | Improved reliability, easier thermal design |

| Meets energy standards | Compliance with regulations (e.g., Energy Star, ErP) |

Efficient chargers convert more of the input power into usable output power. This is good for the environment and the user’s wallet. It also makes the charger run cooler, which is important for longevity and safety. Designing for efficiency involves selecting the right components and optimizing the circuit design.

Power Density

Power density refers to how much power a charger can deliver relative to its volume or weight. Higher power density means more power in a smaller package.

| Benefit of High Power Density2 | Impact |

|---|---|

| Smaller charger size | More portable, less cluttered |

| Lighter weight | Easier to carry |

| Attractive design | Appeals to consumers seeking compact products |

Consumers often prefer smaller, more portable chargers, especially for travel or for use with laptops. Technologies like GaN are key to achieving high power density. However, cramming more power into a smaller space makes thermal management more challenging. Heat needs to be dissipated effectively to prevent overheating.

Safety

Safety3 is the most critical factor. Chargers must protect users and their devices from electrical hazards, fire, and overheating.

| Aspect of Charger Safety | Protection Against |

|---|---|

| Electrical Isolation | Electric shock |

| Over-voltage Protection | Damage from power surges |

| Over-current Protection | Damage from excessive current drawing |

| Over-temperature Protection | Fire hazard, component damage |

| Flammability of Materials | Spread of fire if internal fault occurs |

A charger must meet rigorous safety standards (like UL, CE, CCC) to be legally sold and used. These standards require testing for electrical insulation, temperature limits, fault conditions, and material flammability. No matter how efficient or small a charger is, it must be safe. This is where cost and complexity often increase.

How is the Balance Achieved in Charger Design?

Are you curious about the technical methods used to find this balance? How do engineers manage these competing demands?

Achieving the right balance involves careful component selection, circuit design optimization, and thermal management strategies. New technologies play a big role.

It’s a job for skilled engineers who understand the physics of power conversion and thermal dynamics. They have to make choices about cost, performance, and reliability at every step of the design process.

Advanced Components

Using advanced components is key to improving efficiency and power density while maintaining safety.

| Component Type | Benefit for Charger Design |

|---|---|

| GaN Transistors | Higher efficiency, lower heat, smaller size |

| High-frequency Magnetics | Smaller transformers and inductors |

| Integrated Controllers | Reduce component count, improve efficiency |

GaN transistors are a prime example. They can switch much faster and handle higher voltages than traditional silicon transistors, leading to higher efficiency and allowing for smaller, lighter components like transformers and capacitors. This is why GaN chargers are significantly smaller than older chargers of the same power output. Choosing high-quality components is also essential for reliability and safety.

Optimized Circuit Topologies

The way the circuit is designed affects efficiency, size, and safety.

| Circuit Topology | Advantage |

|---|---|

| Flyback | Simple, cost-effective (lower power) |

| LLC Resonant | High efficiency (higher power) |

| Active Clamp Flyback | Improved efficiency, reduced switching losses |

Different circuit topologies are used depending on the required power level. More complex topologies like LLC resonant converters are used for higher power chargers to achieve better efficiency, even though they require more components. Engineers optimize the circuit layout to minimize energy losses and reduce electrical noise, which helps with efficiency and electromagnetic compatibility (EMC) requirements.

Thermal Management

Controlling heat is critical for safety and reliability, especially in high-power-density designs.

| Thermal Management Technique | How it Works |

|---|---|

| Heat Sinks | Absorb and dissipate heat |

| Thermal Paste/Pads | Improve heat transfer from components |

| Air Vents/Casings | Allow heat to escape the enclosure |

| Temperature Sensors | Monitor temperature, trigger shut-down |

As chargers get smaller and more powerful, heat becomes a major challenge. Components generating heat need paths to dissipate it away. This involves using materials that conduct heat well, adding heat sinks if necessary, and designing the casing to allow for airflow (passive cooling). Built-in temperature sensors are also crucial safety features, allowing the charger to reduce power or shut down if it gets too hot.

Protection Circuitry

Robust protection circuits are essential for safety, acting as safeguards against faults.

| Protection Type | How it Works |

|---|---|

| Over-voltage Protection | Shuts down or limits voltage if it goes too high |

| Over-current Protection | Limits current if device tries to draw too much |

| Short-circuit Protection | Immediately shuts down if a short is detected |

| Over-temperature Protection | Shuts down if internal temperature exceeds limit |

These circuits constantly monitor the charger’s operation. If a potentially dangerous condition is detected, like a power surge, excessive current draw by the connected device, a short circuit, or overheating, the protection circuitry will intervene, often by shutting off the output. These are non-negotiable safety features required by all major certification standards.

Conclusion

Balancing energy efficiency, power density, and safety is fundamental to modern USB charger design. It requires advanced components, optimized circuits, thermal management, and robust protection features.

-

Understanding energy efficiency can help you design chargers that save power and reduce heat, enhancing reliability and user satisfaction. ↩

-

Exploring power density will reveal how to create compact, portable chargers that meet consumer demands without sacrificing performance. ↩

-

Learning about safety standards is crucial for ensuring your charger designs are compliant and protect users from hazards. ↩